Common problems of aluminum paste

2020 / 11 / 05

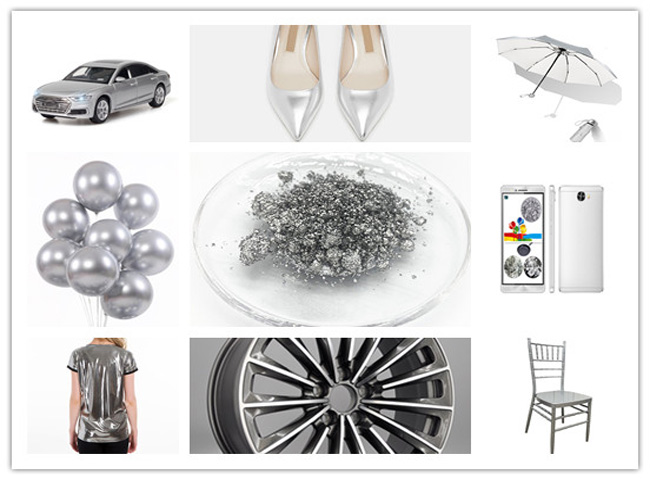

Aluminum paste exists everywhere in our daily life. Aluminum paste is widely used in many fields such as automotive paint, ink, 3C, industrial coating and metallic paint. However, there are several common problems in the use of aluminum paste. Let's just talk about it briefly.

1. Difficult to disperse: mainly caused by improper use of solvents and resins. New resins and solvents can be appropriately prepared. If the product is too fine to disperse, the soaking time can be appropriately extended and stirred at a uniform speed.

2. The aluminum paste may have poor leveling in the use of building materials. When there are adverse reactions in this area, please re-dispense the solvent and adjust it according to the performance of the resin, this may be caused by improper use of solvents and resins.

3. If the product becomes black and yellow during use, it may be that the product is oxidized due to poor sealing, so retest. If yellowing occurs, it is mainly caused by too high baking temperature. Should be baked at a suitable temperature.

4. Particles appear on the surface, which may be black due to oxidation, should be re-tested. If the particles appear due to impurities in the product, should be filtered with filter cloth before use (the filter cloth should be 325 mesh).