Silver aluminum paste: the core material of metal aesthetics and the essence of applicatio

2025 / 03 / 31

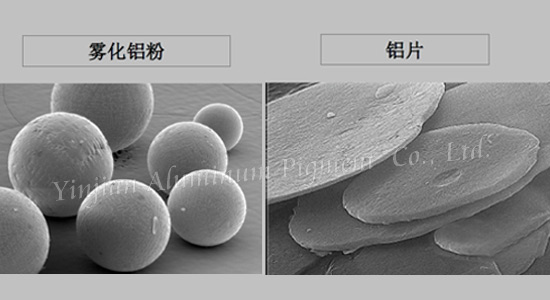

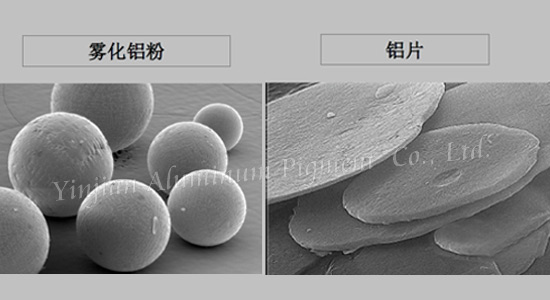

Material Characteristics] Aluminum silver paste is a flake pigment made of 99.7% high purity aluminum standard) by wet process, its diameter-to-thickness ratio (10-50:1) and directional arrangement characteristics, through the parallel reflection of the metallic glittering effect (Flop value>80%), is the core decorative material in the field of automotive paints, industrial paints and other fields.

【Three major applications

Automotive coatings: through the 10-45μm particle size control to achieve the effect of with the angle, Porsche and other brands of original paint aluminum flake orientation> 85%.

Packaging and Printing: Replacing vacuum aluminum plating process, mirror reflectivity increased to more than 90%.

Engineering plastics: 3-5% addition can simultaneously improve thermal conductivity (+25%) and shielding performance

Key to the process] Silver Arrow utilizes a four-stage wet process:

① high purity nitrogen powder (oxygen content <0.3%)

② Compound lubricant wet grinding ( acid / acid amide system)

③Surface modification treatment differential coating)

④Three-stage hydraulic classification ( precise control)

【Innovation Advantage】 Ensured by 23 quality control nodes:

- Flake integrity >95% (est)

- 300℃ high temperature stability

- Solvent content adjustable to 15% (in line with GB 38507)

Silver Arrow Aluminum focuses on the research and development of metal pigments, with products covering 6 major fields and 23 market segments, assisting customers in developing more than 50 new application solutions annually, and driving industrial upgrading with material innovation.

【Three major applications

Automotive coatings: through the 10-45μm particle size control to achieve the effect of with the angle, Porsche and other brands of original paint aluminum flake orientation> 85%.

Packaging and Printing: Replacing vacuum aluminum plating process, mirror reflectivity increased to more than 90%.

Engineering plastics: 3-5% addition can simultaneously improve thermal conductivity (+25%) and shielding performance

Key to the process] Silver Arrow utilizes a four-stage wet process:

① high purity nitrogen powder (oxygen content <0.3%)

② Compound lubricant wet grinding ( acid / acid amide system)

③Surface modification treatment differential coating)

④Three-stage hydraulic classification ( precise control)

【Innovation Advantage】 Ensured by 23 quality control nodes:

- Flake integrity >95% (est)

- 300℃ high temperature stability

- Solvent content adjustable to 15% (in line with GB 38507)

Silver Arrow Aluminum focuses on the research and development of metal pigments, with products covering 6 major fields and 23 market segments, assisting customers in developing more than 50 new application solutions annually, and driving industrial upgrading with material innovation.