Choosing the Right Aluminum Paste: Differences and Advantages of Leafing vs. Non-Leafing

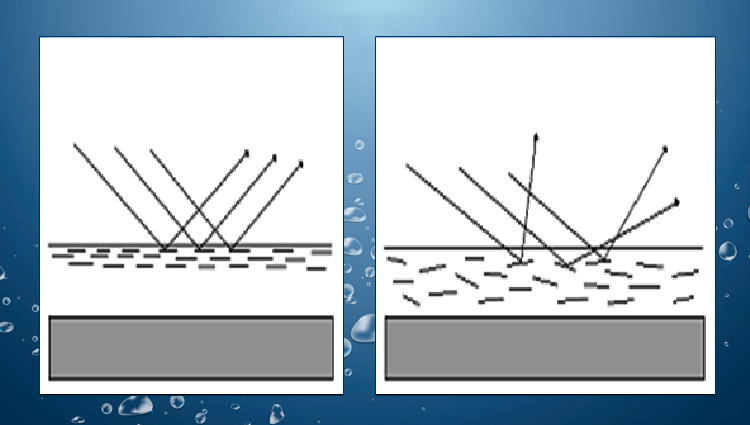

2024 / 08 / 19Leafing aluminum paste, also known as "silver rocket aluminum pigment," forms a high-reflective sheen on the surface of the coating due to its unique low surface tension, as if draping the object in a metallic sheen. This effect is particularly suitable for applications where high gloss and reflectivity are emphasized, such as roof coatings, anti-corrosion coatings, or surfaces like oil tanks and containers. These coatings are not only aesthetically pleasing but also provide excellent protective properties. However, the flake structure may have weaker adhesion in the coating, potentially causing issues in multi-layer coatings, especially when recoating.

In contrast, Non-Leafing aluminum paste exhibits a different set of unique properties. Its particles can be fully encapsulated by the coating system and distributed evenly throughout the film. This means that Non-Leafing aluminum paste settles in the coating, forming a strong and stable protective layer, ideal for applications requiring durability and stability, such as automotive exterior coatings, furniture surface treatments, electronic product casings, and various coil coatings. The advantage of Non-Leafing aluminum paste lies in its strong adhesion, ensuring that the coating is less prone to peeling, maintaining a smooth and even metallic gloss even after multiple coatings.

In summary, if you are aiming for high reflectivity and a metallic decorative effect, Leafing aluminum paste is undoubtedly the best choice; however, if durability and multi-layer coating reliability are what you value, Non-Leafing aluminum paste will better meet your needs. Selecting the right aluminum paste product is crucial depending on the application scenario. If you have any questions or need assistance, feel free to contact us, and we will be happy to recommend the most suitable product solution for you.