Water-Borne Aluminium Paste: The New Standard for Eco-Friendly Metallic Coatings

2025 / 11 / 29With global regulations tightening on VOC emissions, manufacturers are shifting from solvent-based metallic pigments to safer, greener solutions. Water-borne aluminium paste has become a core technology in coatings, offering high brilliance and excellent chemical stability—while meeting strict environmental standards.

What Is Water-Borne Aluminium Paste?

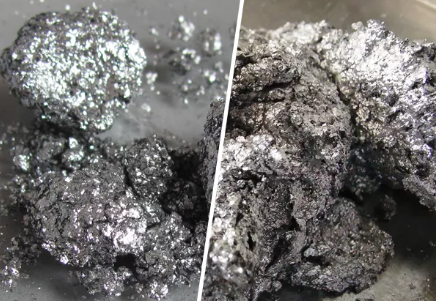

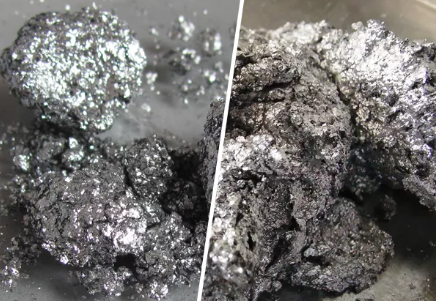

Water-borne aluminium paste is a metallic pigment in which aluminium flakes are specially treated (often with inorganic or resin coatings) to maintain stability in water-based systems.

Its surface treatment prevents direct reaction between aluminium and water—avoiding hydrogen generation and ensuring safety.

Key performance features include:

-

High metallic brightness

-

Excellent gassing stability

-

Improved adhesion & anti-corrosion properties

-

Lower VOC and environmental compliance

Our data (internal stability testing, 2024) shows that high-quality water-borne aluminium pastes maintain gassing levels < 0.5 ml·g⁻¹/24h, significantly safer than untreated aluminium.

Core Technology Behind Water-Borne Aluminium Paste

1. Advanced Surface Coating Technology

To prevent water reaction, aluminium flakes are coated using:

-

Silane treatment

-

Resin encapsulation

-

Inorganic nano-coatings

This creates a barrier layer that:

-

Enhances oxidation resistance

-

Increases storage stability

-

Improves dispersibility in aqueous systems

According to industry benchmarks, coated aluminium flakes have 3–5× higher water resistance than untreated grades.

2. Excellent Gassing Resistance & Safety

Traditional aluminium paste reacts with water to produce hydrogen gas.

Water-borne grades eliminate this hazard by isolating aluminium from moisture.

Typical hydrogen evolution comparison:

| Type | Hydrogen Evolution (24h, 50°C) |

| Untreated aluminium paste | 10–50 ml/g |

| Water-borne aluminium paste | < 0.5 ml/g |

| Premium coated aluminium paste | < 0.2 ml/g |

This is critical for safe storage, transportation, and use in factories.

3. Superior Compatibility in Water-Based Coating Systems

Water-borne aluminium paste is compatible with:

-

Acrylic emulsions

-

PU dispersions

-

Epoxy emulsions

-

Water-reducible alkyds

It disperses easily and maintains a stable metallic effect without flocculation or blackening.

Applications & Performance Comparison

Where Water-Borne Aluminium Paste Performs Best

-

Water-based automotive coatings

-

Industrial anti-corrosion coatings

-

Water-based inks & plastics

-

Architectural coatings

-

Water-based leather coatings

Comparison with Oil-Based Aluminium Paste

| Feature | Water-Borne Aluminium Paste | Oil-Based Aluminium Paste |

| VOC | Low / eco-friendly | High |

| Gassing Stability | Excellent | Medium |

| Brightness | High | Very High |

| Safety | Safe (low hydrogen risk) | Requires stricter control |

| Applications | Water-based systems | Solvent systems |

Despite slightly lower peak brightness compared to solvent-based grades, modern water-borne pigments now achieve 85–95% of solvent-based metallic effect, according to coating industry AAMA standards (2023).

FAQ About Water-Borne Aluminium Paste

1. Does water-borne aluminium paste lose brightness?

Not anymore. Modern coating technology preserves most of the metallic gloss found in solvent-based products.

2. Can it be used in 100% water-based coatings?

Yes. Surface-treated flakes ensure stability even in fully aqueous environments.

3. Will it react and produce gas?

High-quality grades have extremely low gassing (<0.5 ml/g), making them safe.

4. Is it more expensive?

Usually slightly higher due to coating technology, but total cost decreases because of lower VOC treatment requirements.

5. How should it be dispersed?

Gentle stirring is enough—avoid high-speed shear to protect flake integrity.

Water-borne aluminium paste is no longer a future trend—it is the new industry standard for eco-friendly metallic coatings. With superior stability, safety, and environmental compliance, it is replacing solvent-based pigments across Asia, Europe, and North America.

If you need high-brightness, low-gassing, environmentally compliant Water-Borne Aluminium Paste, contact the experts at: