Characteristics of Aluminium pigment

2020 / 09 / 30

Aluminum pigment is a kind of flake effect pigment which is widely used in industry at present. It can be divided into leafing type and non leafing type. Non leafing aluminum pigment occupies most of the market share of more than 80%.

Non leafing aluminum pigment include those with larger particle size and fine grain size showing Satin luster.

Most of the leafing pigments are arranged on the surface of the coating film, showing bright and even chromium plating effect of the film appearance, and the covering power is excellent. The characteristics of aluminum pigment on the surface of powder coating or coating are as follows

1.Covering and shielding

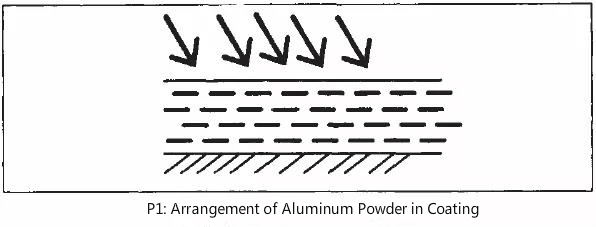

The aluminum pigment is scaly or corn flakes, and the diameter / thickness ratio of the substrate is about (40:1) ~ (100:1) particles are arranged in parallel in the coating film, forming a continuous multi-channel aluminum pigment layer covering the substrate, reflecting the incident light. The pores of each layer of aluminum pigment interlace each other, cutting off the path between the pores of the coating film and the external water, making it difficult for moisture to enter the coating film and reach the substrate(P1)

2.Optical Characteristics

Aluminum pigment is made of metal aluminum with high luster, light color and high purity. After processing, the surface of aluminum particles become smooth and the reflectivity of visible light, infrared light and ultraviolet light with wavelength of 280 ~ 400nm reaches 60% ~ 90%, showing a silvery white appearance.

3."Heterochromatic effect with angle"

Aluminum pigment has the characteristics of metallic luster and parallel to the surface of the coating. In the transparent or poor hiding power coating system, the glossiness and color tone of aluminum particles will affected by the change of incident angle and observation angle, which is usually called "two color effect" or "interference effect". Of course, the good parallel orientation of aluminum pigment (aluminium flake) is the premise of producing the optical effect.

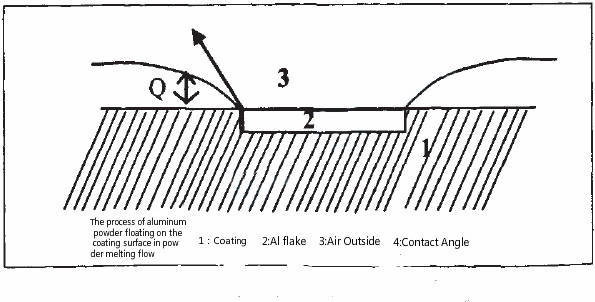

4. Floatability

In the production process, the surface of flake aluminum powder is coated with high-grade fatty acid. The fatty acid on the surface of aluminum powder has two adsorption layers. The lipophilic group of the outer fatty acid is connected with the lipophilic group of the inner fatty acid to make the carboxyl group outward. Therefore, the fatty acid coating in the aluminum powder is an oil repellent powder melting flow. In general, aluminum particles migrate to the coating surface under the action of "Bernard vortex", making the aluminum powder float on the coating surface Layer surface.

When there is no organic matter coating on the surface of aluminum(pigment) powder, the floating force of aluminum powder is small, and it is difficult to migrate to the surface of coating film. The factors affecting the floating ability of aluminum pigment include fatty acid type, diameter / thickness ratio of aluminum powder scale, processing technology and temperature of aluminum powder, particle size of aluminum powder, etc.

The surface treatment process of non leafing aluminum pigment is to select unsaturated fatty acid coating or change the grinding temperature of aluminum pigment, so as to increase the overall proportional of aluminum flake particles and coating film, showing oil drainage characteristics

All rights reserved by Zhangqiu Metallic Pigment